Understanding the Need for Speed in Die Cutting

In today’s fast-paced manufacturing environment, time is money. Businesses across various industries are constantly seeking ways to streamline their processes and increase productivity. One area where efficiency is paramount is die-cutting. The ability to perform rapid die cut operations can significantly impact a company’s bottom line, improving turnaround times and meeting tight deadlines.

What is Rapid Die Cutting?

Rapid die cutting refers to the process of quickly and efficiently cutting materials into specific shapes using advanced machinery and techniques. This method is essential for industries such as:

- Packaging

- Automotive

- Electronics

- Medical devices

- Aerospace

The Benefits of Rapid Die Cutting Services

Embracing rapid die cut technology offers numerous advantages:

- Increased production speed

- Improved accuracy and consistency

- Reduced material waste

- Greater flexibility in design options

- Cost-effectiveness for both small and large runs

Key Technologies Driving Rapid Die Cutting

Several technological advancements have revolutionized the die cutting industry:

Digital Die Cutting

Digital die cutting eliminates the need for physical dies, offering:

a) Quicker setup times

b) Easy design modifications

c) Reduced tooling costs

d) Ideal for prototyping and small batch production

Laser Die Cutting

Laser technology provides precision and speed:

- Contactless cutting for delicate materials

- Ability to create intricate designs

- Reduced wear and tear on equipment

- Suitable for a wide range of materials

High-Speed Rotary Die Cutting

Perfect for high-volume production:

- Continuous operation for maximum efficiency

- Capable of handling multiple layers simultaneously

- Ideal for large-scale packaging and label production

- Minimizes material waste through optimal nesting

Optimizing Your Die Cutting Process

To truly maximize efficiency with rapid die cut services, consider these strategies:

Material Selection and Preparation

Choosing the right materials is crucial:

- Opt for materials that are compatible with high-speed cutting

- Ensure proper storage and handling to prevent warping or damage

- Consider pre-treating materials for improved cutting performance

Die Design and Maintenance

Effective die design can significantly impact speed and quality:

a) Utilize computer-aided design (CAD) for precision

b) Implement modular die systems for quick changeovers

c) Regularly maintain and sharpen dies to ensure optimal performance

d) Consider using multi-up dies for increased productivity

Workflow Optimization

Streamline your production process:

- Implement automated material feeding systems

- Use conveyor systems for efficient material handling

- Integrate quality control measures throughout the process

- Utilize software for production scheduling and tracking

The Role of Automation in Rapid Die Cutting

Automation is key to achieving maximum efficiency:

- Robotic arms for material handling and die-changing

- Vision systems for precise alignment and quality control

- Integrated software for seamless operation and data collection

- Automated packaging and sorting systems

Customization and Flexibility in Rapid Die Cutting

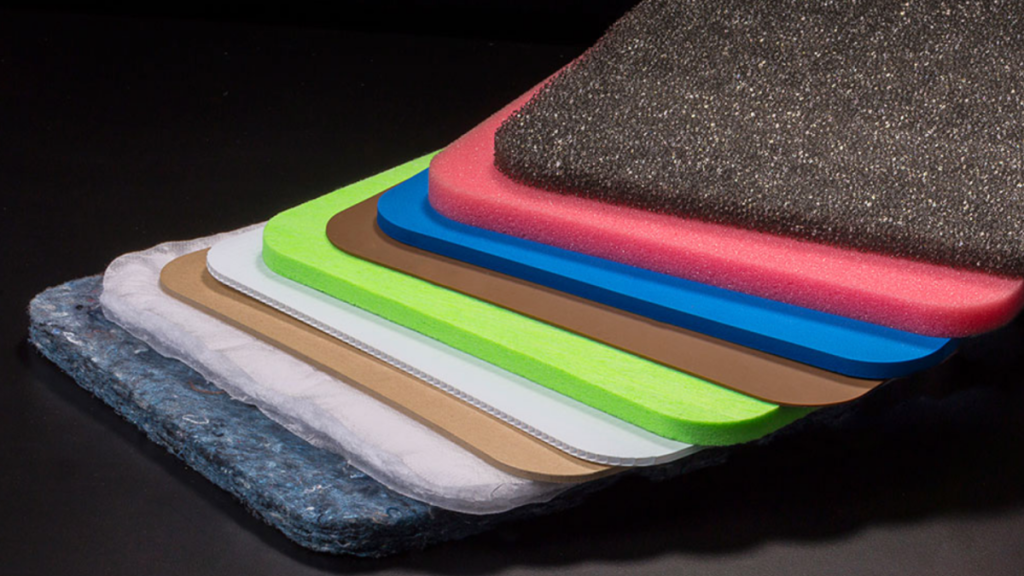

Modern rapid die-cut services offer unprecedented flexibility:

a) Quick turnaround for custom designs

b) Ability to handle a variety of materials and thicknesses

c) Easy scaling from prototypes to full production runs

d) On-demand production capabilities

Environmental Considerations in Rapid Die Cutting

Efficiency doesn’t have to come at the cost of sustainability:

- Implement recycling programs for material waste

- Utilize energy-efficient machinery

- Explore eco-friendly materials and adhesives

- Optimize nesting to reduce material consumption

Training and Skill Development for Rapid Die Cutting

Investing in your workforce is essential:

- Provide comprehensive training on new technologies

- Encourage continuous learning and skill improvement

- Foster a culture of innovation and efficiency

- Implement cross-training to ensure operational flexibility

Quality Control in High-Speed Die Cutting

Maintaining quality while increasing speed is paramount:

a) Implement in-line quality control systems

b) Utilize statistical process control methods

c) Regularly calibrate equipment for consistent results

d) Conduct routine quality audits and inspections

The Future of Rapid Die Cutting

As technology continues to evolve, we can expect to see:

- Integration of artificial intelligence for predictive maintenance

- Advanced materials that are easier and faster to cut

- Increased automation and lights-out manufacturing capabilities

- Greater integration with other manufacturing processes

Choosing the Right Rapid Die-Cutting Service

When selecting a rapid die-cut service provider, consider:

- Their technological capabilities and equipment

- Experience with your specific industry and materials

- Turnaround times and production capacity

- Quality control measures and certifications

- Flexibility in handling custom projects and rush orders

Embracing rapid die-cutting technology is no longer a luxury but a necessity for businesses looking to stay competitive in today’s fast-paced market. By leveraging advanced machinery, optimizing workflows, and focusing on continuous improvement, companies can significantly enhance their production capabilities.

The ability to perform rapid die cut operations not only improves efficiency but also opens up new possibilities in product design and customization. As the technology continues to evolve, businesses that adapt and integrate these advancements into their operations will be well-positioned to meet the ever-increasing demands of modern manufacturing.

Remember, the key to success in rapid die-cutting lies not just in the technology itself but in how well it’s implemented and managed within your overall production process. By focusing on optimization, training, and quality control, you can ensure that your rapid die-cutting operations truly operate at the speed of business, driving your company forward in an increasingly competitive landscape.