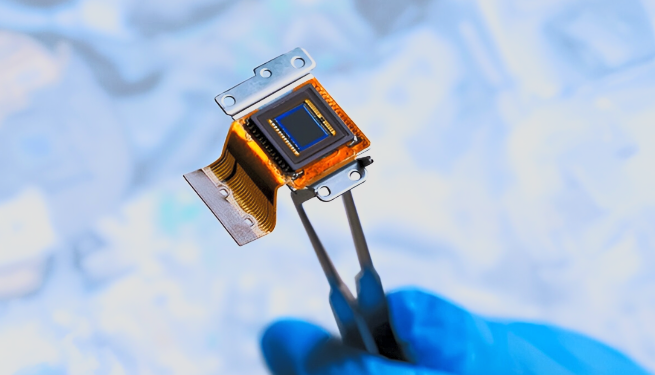

Rigid flex PCB assembly combines the durability of rigid boards with the adaptability of flexible circuits, offering a hybrid solution that enhances electronic product design. These PCBs are built using multiple layers of rigid and flexible substrates laminated together, allowing certain sections to bend while others remain stable. This unique configuration provides excellent mechanical stability, space efficiency, and electrical performance in compact or complex electronic devices.

Unlike traditional rigid PCBs, which are limited to fixed shapes, rigid flex boards can fold and twist during assembly, making them ideal for applications where space constraints or motion are critical. From aerospace and medical devices to consumer electronics and wearable technology, rigid flex PCB assembly has become the preferred choice for engineers seeking high reliability and optimized performance.

The Structure and Design of Rigid Flex PCB Assembly

The architecture of a rigid flex PCB assembly involves multiple rigid layers connected through flexible circuits. These flexible layers act as interconnects, allowing movement between rigid sections without the need for connectors or additional wiring.

Designing a rigid flex board requires precise engineering to manage factors such as bend radius, trace routing, copper thickness, and stress points. Engineers also must consider signal integrity and mechanical stability during flexing, as improper design could lead to cracks or delamination. Advanced CAD software and 3D modelling tools are used to simulate the final assembly and ensure that the board fits perfectly within the end device.

Manufacturing Process of Rigid Flex PCB Assembly

The production of rigid flex boards is more complex than standard PCB manufacturing because it involves integrating flexible and rigid materials seamlessly. Here’s a simplified overview of the process:

1. Material Selection and Layer Preparation

High-quality base materials like polyimide for the flexible section and FR4 for the rigid layers are selected. The material choice directly influences durability, flexibility, and signal transmission performance.

2. Circuit Imaging and Etching

Conductive copper patterns are created on both rigid and flexible layers using photolithography and etching processes. This defines the electrical pathways for the circuit.

3. Lamination

The rigid and flexible sections are laminated together under heat and pressure using adhesive or adhesive-less bonding. This step requires extreme precision to avoid misalignment or damage to the flex areas.

4. Drilling and Plating

Holes are drilled to form vias and through-holes that interconnect different layers. Afterward, copper plating is applied to ensure proper conductivity between layers.

5. Component Assembly

The next stage involves the rigid flex PCB assembly, where components are placed on both rigid and flexible areas using Surface Mount Technology (SMT) or Through-Hole Technology (THT). Reflow soldering and selective soldering are applied based on the material’s thermal tolerance.

6. Testing and Inspection

Each assembled board undergoes rigorous quality checks such as Automated Optical Inspection (AOI), X-ray analysis, and electrical testing. This ensures that the flex zones perform correctly and that there are no short circuits or open connections.

Advantages of Rigid Flex PCB Assembly

The rigid flex PCB assembly process offers numerous benefits that make it superior to conventional PCB designs:

Compact and Lightweight Design

By eliminating connectors and cables, rigid flex PCBs reduce overall product weight and size — an essential advantage in portable and space-limited devices.

Enhanced Reliability

Since there are fewer mechanical connections, the likelihood of signal failure or loose joints decreases significantly. The integrated structure improves durability in high-vibration and high-stress environments.

Improved Signal Integrity

The direct interconnection between rigid and flexible sections minimizes interference and impedance issues, resulting in better signal transmission and stability.

Greater Design Freedom

Engineers can design complex 3D configurations that would be impossible with traditional boards. The flexibility of the circuit enables creative and efficient product layouts.

Cost Efficiency for High-End Products

Although initial manufacturing costs are higher, rigid flex designs often reduce the need for connectors and assembly steps, leading to long-term savings in high-performance products.

Common Applications of Rigid Flex PCB Assembly

Rigid flex PCB assembly is used in industries where reliability, compactness, and mechanical endurance are paramount. Common applications include:

- Aerospace and Defence: Navigation systems, avionics, and rugged communication devices.

- Medical Devices: Pacemakers, imaging equipment, and portable diagnostic tools.

- Consumer Electronics: Smartphones, cameras, and foldable gadgets.

- Automotive: Control modules, airbag systems, and infotainment devices.

- Industrial Equipment: Sensors, robotics, and automation control systems.

In all these fields, the combination of flexibility and rigidity ensures consistent performance even under demanding conditions.

Design Challenges and Considerations

While rigid flex PCB assembly offers multiple benefits, it also requires meticulous planning. Engineers must account for dynamic bending zones, thermal expansion, and proper component placement to prevent mechanical stress. Additionally, routing traces through the transition areas between rigid and flex sections needs careful optimization to maintain electrical stability.

Thermal management is another key factor since the flexible section typically has different heat resistance compared to rigid layers. Using high-grade materials and precise lamination techniques ensures the final product maintains performance across temperature variations.

The Future of Rigid Flex PCB Assembly

As electronics continue to evolve, the demand for miniaturized yet powerful devices keeps rising. Rigid flex PCB technology is expected to play an even more critical role in next-generation electronics such as wearable devices, electric vehicles, and aerospace systems. The ongoing advancements in material science, laser drilling, and 3D integration are pushing the boundaries of what rigid flex PCBs can achieve.

Manufacturers are also integrating advanced testing automation and AI-assisted design to streamline the production of highly reliable boards. These innovations are making rigid flex PCBs more accessible and cost-effective for diverse industries.

Conclusion

Rigid flex PCB assembly represents the ideal solution for applications that demand both durability and flexibility. It simplifies product design, enhances reliability, and optimizes electrical performance — all while reducing space and weight. By integrating flexible and rigid layers, this hybrid technology delivers outstanding results in complex and compact devices.

For achieving consistent quality and precision, it’s essential to partner with the best PCB assembly service that understands the intricacies of rigid flex technology. A professional assembly partner can help transform your designs into high-performance, production-ready boards, ensuring that your products meet industry standards and exceed customer expectations.